Air valve mechanism

Air volume control valve actua

Air valve actuator

Remote controller for smoke ex

Air conditioning accessories

tuyere

Air valve actuator

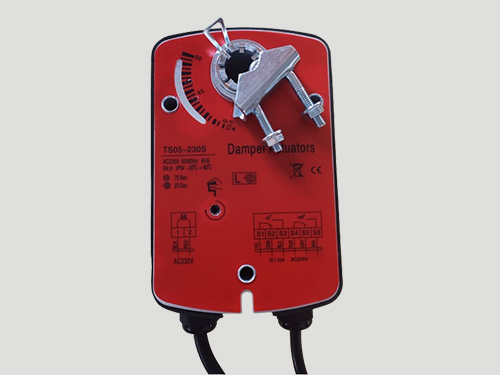

As an important industrial automation equipment, damper actuators are widely used in many fields. They are mainly used to control the opening and closing of dampers to adjust air flow and pressure. The following are some of the main application scenarios of damper actuators:

1. Air conditioning system

Application scenario: In the air conditioning system, the damper actuator is used to control the damper switch in the indoor air conditioning system to control the indoor air flow mode. By adjusting the opening of the damper, the indoor air flow can be accurately controlled to maintain the stability of indoor temperature, humidity and air quality.

Advantages: Improve indoor comfort, save energy and reduce energy consumption.

2. Ventilation system

Application scenario: In the ventilation system of the building, the damper actuator is used to control the damper switch in the ventilation duct to achieve indoor air flow regulation. This helps to maintain the freshness and cleanliness of the indoor air and prevent the accumulation of pollutants and harmful gases.

Advantages: Improve indoor air quality and protect the health of personnel.

3. Purification system

Application scenario: In the purification system, the damper actuator is used to control the damper switch in the purification equipment to ensure that the air purification effect is as expected. By precisely controlling the opening of the air valve, the operating efficiency of the purification equipment can be optimized and the air purification quality can be improved.

Advantages: Ensure air cleanliness and meet the high requirements of air quality in special environments.

IV. Industrial production line

Application scenario: In industrial production lines, air valve actuators can be used to control the airflow control of heating equipment, cooling equipment, etc. to improve product quality and production efficiency. For example, in a heat treatment furnace, the air valve actuator can control the flow and temperature of the cooling air to accurately control the cooling speed and temperature distribution of the workpiece.

Advantages: Improve the stability and controllability of the production process and reduce the scrap rate.

V. Energy system

Application scenario: In the energy system, the air valve actuator can be linked with the energy equipment to adjust the airflow in real time according to the energy supply to improve energy utilization efficiency. For example, in a gas turbine or wind power generation equipment, the air valve actuator can control the opening of the air inlet to optimize the operating efficiency and power output of the equipment.

Advantages: Improve energy utilization efficiency and reduce operating costs.

6. Other fields

Sewage treatment system: The air valve actuator can control the ventilation equipment in the sewage treatment system to achieve sewage treatment and discharge, and protect the environment.

Pharmaceutical industry: In the pharmaceutical process, the air valve actuator can be used to control the flow and mixing of liquid medicine and other media to ensure the accuracy and safety of the pharmaceutical process.

Laboratories and machine rooms: In laboratories and machine rooms, air valve actuators can be used to control the pipes and valves of cold, hot water, low-pressure steam and other media to meet the high requirements of special environments for parameters such as temperature and humidity.

In summary, air valve actuators are widely used in air conditioning systems, ventilation systems, purification systems, industrial production lines, energy systems and many other fields. With the continuous development of automation technology, the performance and application scope of air valve actuators will continue to expand and improve.

Working principle of the actuator of the air volume control valve

Electric air volume control valve, as an intelligent air duct equipment, is widely used in air conditioning systems in fields such as construction, medical care, and industry. It can automatically adjust the opening of the valve according to the air flow

2024-05-06

The execution content of the fire damper actuator

To drive the valve action, a matching actuator is required. The actuator used for fire dampers may not be electrically driven, but may also be electrically driven.

2024-05-06

The structural composition of the fire damper actuator

The fire damper actuator is a type of actuator used for fire dampers in ventilation and air conditioning system pipelines, which solves the problem of inaccurate adjustment of the opening angle of valve blades, thus unable to accurately control the ventil

2024-05-06

What functions can the actuator of the air volume control valve achieve?

The actuator of the air flow regulating valve is an automated equipment used to control the air flow valve in ventilation ducts. It can automatically adjust the opening of the air valve by receiving signals from the control system to achieve the goal of c

2024-05-06