Air valve mechanism

Air volume control valve actua

Air valve actuator

Remote controller for smoke ex

Air conditioning accessories

tuyere

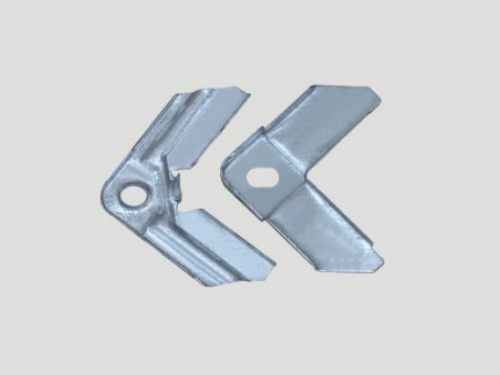

Air duct valve corner code

Duct-valve angle bracket (or angle bracket flange) is a main accessory used to connect ducts and valves in HVAC systems. The following is a detailed analysis of it:

1. Concept and function

Concept: Duct-valve angle bracket, as a key component connecting ducts and valves, achieves a stable connection between the two through its unique structure and material. It usually consists of two main parts: an angle bracket and a flange, which are connected by fasteners such as bolts.

Function: In HVAC systems, the stable connection between ducts and valves is crucial to the overall performance and stability of the system. Duct-valve angle bracket can effectively fix the duct and valve together to prevent loosening or falling off due to vibration or external force, thereby improving the stability and reliability of the system. At the same time, it can also reduce the noise generated by the operation of the duct to a certain extent and optimize the operation effect of the system.

2. Structure and material

Structure: The structural design of the duct-valve angle bracket usually takes into account the convenience and aesthetics of installation. Its shape and size usually match the interface of the duct and valve to ensure the accuracy and smoothness of installation. At the same time, the angle code will also be provided with corresponding holes to facilitate the installation and fixing of fasteners such as bolts.

Material: Duct-air valve angle codes are usually made of high-strength materials, such as high-quality steel, aluminum alloy, etc. These materials not only have sufficient load-bearing capacity and stability, but also can resist corrosion and wear to a certain extent, thereby extending the service life of the angle code.

3. Specifications and models

The specifications and models of duct-air valve angle codes vary depending on the manufacturer and application scenario. Common specifications and models include JGD, JGW, JBJ, JGDs, etc. When selecting an angle code, it is necessary to comprehensively consider factors such as the specific size of the duct and air valve, the interface type, and the operating requirements of the system to ensure that the selected angle code can meet actual needs.

4. Installation and maintenance

Installation: The installation of duct-air valve angle codes needs to follow certain specifications and processes. Before installation, the interface of the duct and air valve needs to be cleaned and inspected to ensure that the interface is flat and free of impurities. Then, place the angle code at the interface and connect it tightly to the duct and air valve through fasteners such as bolts. During the installation process, attention should be paid to the tightening force and sequence of the bolts to ensure the stability and sealing of the connection.

Maintenance: Regular inspection and maintenance of the duct-air valve angle code is the key to ensure its long-term stable operation. The inspection content includes the tightness of the angle code, whether it is loose or falling off, whether it is corroded or worn, etc. For any problems found, timely measures should be taken to deal with them, such as re-tightening the bolts, replacing damaged angle codes, etc.

In summary, the duct-air valve angle code plays a vital role in the HVAC system. Through reasonable selection and installation, as well as regular maintenance and care, a stable connection between the air duct and the air valve can be ensured, and the overall performance and stability of the system can be improved.

Working principle of the actuator of the air volume control valve

Electric air volume control valve, as an intelligent air duct equipment, is widely used in air conditioning systems in fields such as construction, medical care, and industry. It can automatically adjust the opening of the valve according to the air flow

2024-05-06

The execution content of the fire damper actuator

To drive the valve action, a matching actuator is required. The actuator used for fire dampers may not be electrically driven, but may also be electrically driven.

2024-05-06

The structural composition of the fire damper actuator

The fire damper actuator is a type of actuator used for fire dampers in ventilation and air conditioning system pipelines, which solves the problem of inaccurate adjustment of the opening angle of valve blades, thus unable to accurately control the ventil

2024-05-06

What functions can the actuator of the air volume control valve achieve?

The actuator of the air flow regulating valve is an automated equipment used to control the air flow valve in ventilation ducts. It can automatically adjust the opening of the air valve by receiving signals from the control system to achieve the goal of c

2024-05-06