Air valve mechanism

Air volume control valve actua

Air valve actuator

Remote controller for smoke ex

Air conditioning accessories

tuyere

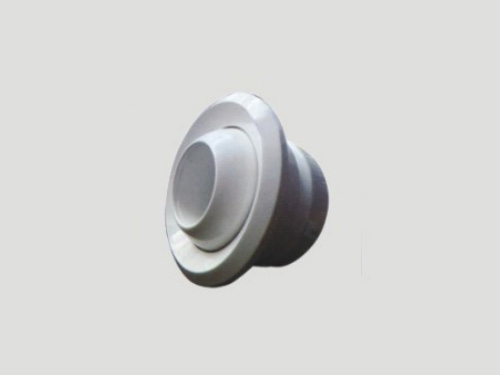

Ball shaped nozzle

Spherical nozzles, also known as spherical nozzles, are a type of equipment widely used in multiple industrial fields and specific environments. The following is a detailed introduction to spherical nozzles:

1. Definition and classification

A spherical nozzle is a nozzle with a spherical nozzle. Its nozzle is designed to be spherical and is equipped with an aluminum decorative ring and a circular pipe that can be directly plugged into a circle. Depending on the control system, spherical nozzles can be divided into various types such as pneumatic, electric and temperature-controlled.

2. Structural design

A spherical nozzle usually consists of a shell, a swirl plate, a nozzle and an inlet pipe. The shell is the outer protective layer of the nozzle, and the swirl plate is located inside the nozzle to change the flow direction and speed of the medium and produce a vortex-shaped jet flow. The nozzle is the outlet of the spray medium, and the inlet pipe is the channel for the medium to enter.

3. Functional characteristics

Air supply and air supply adjustment:

Spherical nozzles are mainly used in environments where the air supply outlet of the air conditioner is far away from the range of personnel activities, such as concert halls, theaters, museums, cinemas, airports, high-speed rail stations, etc.

The air supply nozzle is spherical and stuck in the shell. It can swing within the range of plus or minus 30 degrees through the actuator to adjust the air supply direction.

Pneumatic or electric actuators and temperature-controlled nozzles can be provided as needed. The latter can automatically sense the air flow temperature and automatically drive the inner nozzle to change the air supply angle.

Noise control:

The spherical nozzle adopts the best aerodynamic nozzle structure design to achieve ideal noise control effect, which is suitable for places with high noise requirements.

High efficiency:

The design of the swirl plate enables the nozzle to produce a high-speed vortex-shaped jet flow, which improves the injection efficiency and accuracy, and is suitable for the media injection needs in various chemical production processes.

Durability:

The spherical nozzle has the advantages of high strength, wear resistance and chemical corrosion resistance, and can be used for a long time in harsh industrial environments.

Installation and maintenance:

The spherical nozzle can be installed on the side wall of a square or circular pipe, fixed with bolts or rivets, and a sealing gasket should be placed at the connection.

Easy to install, and some models such as temperature-controlled nozzles have the advantage of maintenance-free.

IV. Application Scenarios

The application scenarios of spherical nozzles are very wide, covering multiple industrial fields and specific environments:

Air conditioning and air supply: used in air conditioning and air supply systems of high-end places such as concert halls, theaters, museums, and cinemas.

Industrial production: in chemical, metallurgical, environmental protection and other industries, it is used for gas injection, liquid spraying, gas mixing and other processes to improve the mixing effect and reaction speed of the reactor.

Cleaning and dust removal: in low-pressure applications such as cleaning, spraying, and cooling, the spherical nozzle separates dust from the air through rotation and impact to achieve efficient dust removal.

Flow control and homogenization: in the production process where the material needs to be flow controlled and homogenized, the spherical nozzle can achieve precise adjustment and homogenization of the material flow by adjusting its opening and rotation angle.

Working principle of the actuator of the air volume control valve

Electric air volume control valve, as an intelligent air duct equipment, is widely used in air conditioning systems in fields such as construction, medical care, and industry. It can automatically adjust the opening of the valve according to the air flow

2024-05-06

The execution content of the fire damper actuator

To drive the valve action, a matching actuator is required. The actuator used for fire dampers may not be electrically driven, but may also be electrically driven.

2024-05-06

The structural composition of the fire damper actuator

The fire damper actuator is a type of actuator used for fire dampers in ventilation and air conditioning system pipelines, which solves the problem of inaccurate adjustment of the opening angle of valve blades, thus unable to accurately control the ventil

2024-05-06

What functions can the actuator of the air volume control valve achieve?

The actuator of the air flow regulating valve is an automated equipment used to control the air flow valve in ventilation ducts. It can automatically adjust the opening of the air valve by receiving signals from the control system to achieve the goal of c

2024-05-06